Can Pedestrian Operated Electric Tugs Reduce Labor Costs in Heavy-Duty Industries

Walking electric tugs can effectively reduce labor costs in heavy industries by reducing physical labor, increasing handling efficiency, minimizing injury risks, and reducing personnel requirements and training costs, thus significantly optimizing personnel and operational expenses for companies.

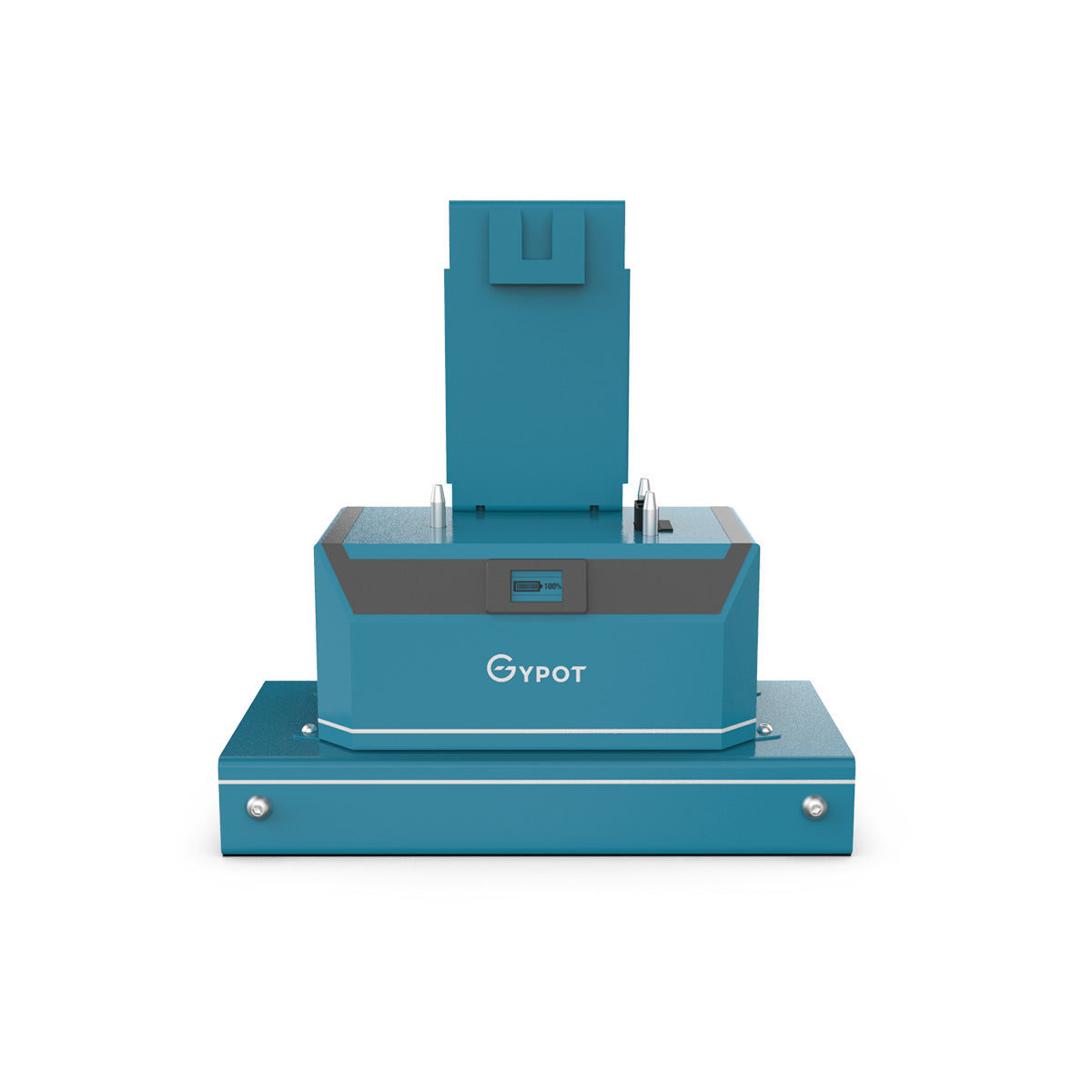

What Are Electric Tugs

The electric tug—a walking electric tug—is a lightweight yet powerful small industrial machine. Its purpose is to assist workers in moving heavy objects that include any additional pulling power through electricity, making it easy to push or pull loads weighing hundreds of kilograms, if not several tons. Most electric tugs work from a battery system, and as such, this makes it easy to recharge, hence suitable for extended use. They are easy to operate; most of them driven by a lever or button that does not need specialized driving training for personnel handling different jobs.

The operating philosophy of electric tugs is simplicity to make the handling process easier and efficient. Compared to the traditional handling equipment, like forklifts, electric tugs are smaller and do not require large areas of flooring. In addition, the walking operation mode enables operators to stop directly where they need it, without losses in efficiency due to spatial limitation. This design makes electric tugs particularly suitable for factories, warehouses, and confined industrial environments, allowing flexibility in handling tasks.

In heavy industries, heavy and frequent material and equipment handling is usually in high demand. Conventional manual handling methods are not only very time-consuming but also require hard physical demands from workers, which often provide safety risks to them. Electric tugs operate so easily and at low cost that they allow the worker to perform the handling task more safely and swiftly. Consequently, electric tugs have gradually become indispensable equipment in industrial production, reducing not only the intensity of physical labor but also improving the overall operational efficiency.

Labor Cost Challenges

Heavy industries have always faced huge labor costs, especially in high-demand work scenarios such as production manufacturing or logistics handling. As labor costs continue to rise across the globe, the expenses related to wages, benefits, and health insurance of workers also increase year by year, thus putting additional cost pressure on business operations. In addition, long-term physical work may lead to worker turnover and increased risk of work-related injuries, which increases the investment in labor for companies.

Worker turnover is yet another major challenge to the labor costs. Heavy industrial work is definitely arduous, and after a while, workers will seek softer and perhaps easier jobs to do, forcing companies to invest much money and time in training new staff. High turnover brings not only recruitment costs but also affects the continuity and stability of the production line; in severe cases, this may eventually decrease production efficiency.

Heavy industries also entail high costs due to work-related injuries and health maintenance. Intensive work can be hazardous to workers, including muscle strains, joint problems, and other health hazards, or even severe injuries such as losing their hands or legs. To ensure the health of workers, companies have to pay high insurance and compensation in cases of work injuries. Therefore, reducing dependence on physical labor and minimizing work injuries are key issues that companies pursue when trying to save labor costs.

Efficiency of Electric Tugs

Their efficiency in industrial production shows that workers can do more in less time. Compared to the traditional handcarts or methods relying on physical strength, electric tugs will save much time in handling since many of them do not require large amounts of manpower to push or lift heavy objects. Simple operation, workers can master and manipulate this tug appropriately for direction and speed changes, hence completing jobs assigned to them with efficiency.

Electric tugs will greatly improve workflow smoothness, especially in heavy industries. During the handling of heavy objects, electric tugs can stably and continuously tow, without causing any stops due to insufficient manpower or fatigue. Besides, electric tugs have strong battery life, and they usually support round-the-clock work requirements, with many tasks able to be executed with just one charge. It can be used again with only a short charge, even when the battery is exhausted, which makes tugs maintain high efficiency in long-term and high-intensity operations.

Another advantage of electric tugs is that they can be applied in any scenario. Whether a straight road, narrow passage, or sloped terrain, electric tugs are capable of working efficiently. The flexible control allows workers to move goods with ease in complicated environments, reducing the complications brought about by either spatial or terrain restrictions. This efficient handling capability improves not only production efficiency but also effectively reduces waiting times during the handling process, avoiding work stoppages that may be caused by untimely material turnarounds.

Benefits in Heavy Industries

The application of electric tugs in heavy industries possesses several advantages. Electric tugs reduce the physical burden on workers from moving heavy objects, decreasing the risk of injuries that result from fatigue, which is important for ensuring workers' health and reducing companies' costs for compensating for work injuries. With this kind of efficient and safe equipment, companies are able to take better care of a safe working environment, improve employee satisfaction, and increase their loyalty.

The flexibility of electric tugs makes them suitable for different industrial environments. Traditional heavy handling equipment often requires ample operating space, but the walking operation design of electric tugs allows workers to maneuver and move goods freely in confined spaces, making them suitable for various narrow and complex work sites. This advantage enables companies to arrange equipment layout and adjustments more flexibly, improving site utilization.

Another significant advantage of electric tugs is that they reduce wear and tear on equipment. Compared to heavy machinery using internal combustion engines or hydraulic systems, electric tugs have lower wear and maintenance costs due to their electric drive systems. The quieter operation of the electric drive system reduces noise pollution, providing workers with a quieter work environment. In the modern-day emphasis on sustainable development, the low carbon emissions of electric tugs also meet the needs of enterprises to reduce their carbon footprint and therefore become a win-win choice for both environmental protection and cost control.

Cost Savings Potential

Electric tugs have immense potentiality for cost savings, not only by directly reducing manpower demand but also by reducing other costs related to labor. Companies are able to reduce the number of employees or reshuffle the available human resources in order to utilize more workers in higher-value-added tasks. In this way, a company can reduce wage and fringe benefits costs by decreasing ineffective physical handling tasks and optimize their labor cost investment accordingly.

The costs associated with the maintenance and upkeep of electric tugs are also relatively low. Because electric tugs have simpler construction without complex engines or hydraulic systems, they have fewer failures and require less frequent maintenance. This also reduces the maintenance and repair cost of the equipment and lowers the cost related to downtime caused by the failure of any equipment. As service life increases, the advantage of low maintenance costs begins to emerge, making an electric tug a very feasible option in cost terms for long use.

More importantly, an electric tug can avoid the conditions leading to damage to cargo due to insufficient manpower or operational errors. While handling heavy burdens in a fatigued state, workers are prone to accidents, whereas the stability of electric tugs ensures the safety of cargo handling without causing product loss due to handling accidents. At the same time, using electric tugs will reduce any incidence of health issues and work injuries, thus saving companies from medical and insurance costs. Indeed, the use of electric tugs has proved to be a long-term, high-return investment.

Safety and Ease of Use

The design of electric tugs is focused on safety and ease of operation, making the equipment more manageable for employees while effectively minimizing risks during the operating process. Electric tugs allow workers to conduct handling tasks with no need to strain themselves by pushing or lifting heavy objects, hence dramatically decreasing the physical load in operations and lowering the chances of work injuries that may be the result of fatigue or bad positioning.

Electric tugs are typically designed with multiple safety features, including automatic braking systems and overload warnings, to ensure workers remain in a safe state during handling. In even the most complicated work environments, stability and maneuverability during handling help workers complete tasks steadily without accidents from site conditions or operational errors. Compared to traditional handling machinery, electric tugs boast a high degree of safety guarantee.

The simplicity of the operation makes electric tugs a tool that "anyone can operate." It only takes a short training period for new workers to get started, which not only shortens the learning curve of the equipment but also reduces equipment damage or handling errors due to unfamiliarity with the operation. In addition, with user-centered design, laborers generally accept this type of equipment and are willing to use electric tugs to replace physical labor, further enhancing the overall work efficiency.