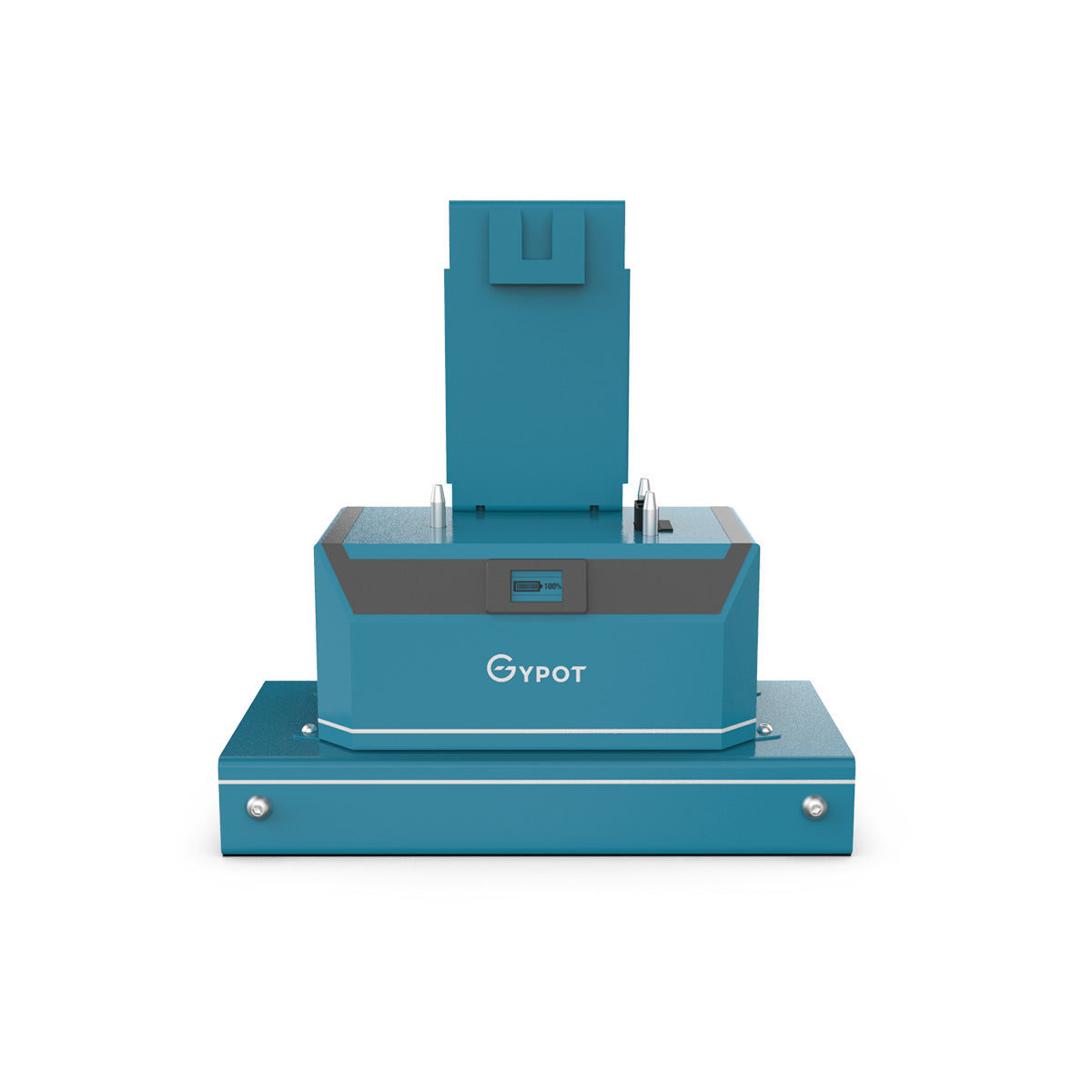

Top 7 Advantages of using electric power tugs in industrial settings

The application of electric tugs in industrial environments has significant advantages, not only enhancing workplace safety but also greatly reducing physical strain on workers. Powered by electricity, they lower operating costs, exhibit excellent maneuverability, and perform efficiently in confined spaces. The eco-friendly features of electric tugs meet modern factories' demands for low emissions and low noise, and they support various attachments to better accommodate different transport tasks. Through the appropriate configuration of electric tugs, factories can optimize logistics processes, improve productivity, and achieve multi-task handling.

Enhanced Safety

In industrial production, safety is a very important factor in workplace operations. The effective application of electric tugs reduces the strain and potential accidents that workers face due to long handling of heavy loads. Traditional manual handling methods put immense physical pressure on workers and may lead to incorrect posture or operational errors when moving heavy loads, creating various safety risks. Electric tugs boast of stable and controlled heavy load transportation through a motor-driven and precise load distribution design that ensures proper operation, preventing goods from slipping or colliding.

Moreover, it could be equipped with an automatic braking system, speed-limiting devices, and soft start control, so that tugging operation can accelerate and decelerate smoothly to avoid violent shaking of goods in transit. Additionally, the emergency stop button increases the safety response of the equipment in emergency situations. More importantly, lots of electric tugs have overload protection functions or a safety locking mechanism to avoid risks caused by overloading or misuse, so as to basically enhance equipment safety.

Increased Efficiency

Material handling in the industrial environment benefits greatly from electric tugs, with an increase in efficiency compared to traditional approaches. Traditionally, handling methodologies involve a lot of manual and hand-push gear, which only has limited speed and is easily affected by the fatigue of the workers, hence leading to inefficiency. The motor drive of the electric tug offers constant and stable power output so that the transporting work can be done efficiently for a long period. Especially in high-volume production and fast logistics scenarios, the material flow and product dispatching can be considerably accelerated.

High-performance batteries allow the electric tugs to work without any problem for continuous shifts, simply requiring intermittent charging to meet demands of 24/7 usage. Electric tugs reduce material handling time with heavy loads and optimize the business process and use of resources where businesses have to do this often. The other advantage with electric tugs is the custom options availed by their modular design for different production needs. In distributing materials, it enables operators to put goods in precise, fixed positions quickly and efficiently, which greatly reduces the offsets and errors compared with the traditional handling method, and can minimize the secondary handling that consumes a lot of time.

Lower Operating Costs

Traditional diesel-powered tractors burn large quantities of fuel and require considerable periodic maintenance, whereas electric tugs use electric power to guarantee low energy costs with no environmental pollution. The body structure for an electric tug is simple with small mechanical friction in operation, and the wear of parts is slow with long intervals between maintenance. This is a design feature that effectively minimizes the frequency and cost of maintenance and considerably lowers the overall running cost.

The power battery management system of the electric tug optimizes the charging/discharging process and further prolongs service life. Besides, different from fuel-powered equipment, electric tugs can usually be modularly expanded in their own battery packs on the basis of actual use requirements, which means it's convenient to control the battery load and prolong the service life of the equipment. The operating cost of electric tugs is relatively foreseeable in the long run owing to stable prices; it's free from the influence of fuel price fluctuations. Thus, business cost budgeting will be clear and under full control, convenient for long-term capital expenditure planning.

Reduced Worker Fatigue

The mechanization brought about by the electric tug greatly reduces physical exertion for workers. Traditional handling of heavy loads requires prolonged pushing and pulling by workers, especially in transporting high-frequency or large-load goods. Workers easily get fatigued with longer operations, affecting stability in productivity. Electric tugs will have workers performing the task of handling heavy loads with ease, since workers control direction and starting through the control handle, greatly reducing demand for hard labor.

Many electric tugs are also installed with ergonomic control handles and hydraulic lift systems that allow workers to handle equipment more easily, further reducing operational fatigue. Smoothening in acceleration and deceleration functions of electric tugs avoids violent vibration; as a result, it avoids unnecessary impact on workers during the handling process. Such a comfortable and effective operating experience not only helps boost the work motivation of workers but also reduces work-related injuries caused by excessive fatigue, indirectly improving the company's productivity.

Improved Maneuverability

The ground is often limited in industrial settings, especially in storage and production workshops where narrow aisles and densely packed shelving lay a high demand on equipment maneuverability. Electric tugs can easily accomplish various demands at sites due to their compact size and high flexibility. In confined spaces, operators can finish the precise turn and parking operation by using the high sensitivity steering system of electric tugs, avoiding the operational difficulties traditional equipment faces in narrow areas.

Many electric tugs also boast intelligent control systems, comprising path-tracking and automatic obstacle avoidance functions. The intelligent system effectively improves the navigation capability of the equipment in independently planning driving paths in a complex production environment and avoiding collisions. Electric tugs usually have several gears; according to the situation at the site, speed can be adjusted to guarantee the goods are being processed stably and reliably. Electric tugs allow for exceptional maneuverability; hence, they can offer flexible and precise transportation in industry for a wide range of applications effectively by improving space utilization and operational efficiency.

Environmentally Friendly

Due to their characteristics of being green and environmentally friendly, electric tugs have become irreplaceable transportation tools in industrial environments. Compared with the traditional internal combustion engine equipment, electric tugs will totally depend on electric power and consume no fuel at all, nor do they have any exhaust emissions to unfavorably affect air quality; thus, it fully meets the increasing number of businesses about environmental protection and sustainable development goals. Food, pharmaceuticals, and even electronics manufacturing all require stringent control of pollution. The zero-emission features of electric tugs significantly reduce any form of risks of pollution during their production process.

Indeed, one of the important advantages of electric tugs is their low noise. Internal combustion engine equipment normally creates a lot of noise in the process of work, while an electric tug will function much more quietly, which allows it to help in keeping a quiet environment for work and reduces the negative influence of noise on the work state and health of employees. In addition, it is more suitable for a semi-enclosed working site and meets the needs of businesses regarding environmental protection and employee health. In environmental protection, the usage of electric equipment is already an industry trend. Besides following the environmental regulations, an electric tug develops a green image for the business.

Versatile Applications

With their flexible design, electric tugs can be applied to a wide variety of industrial handling needs: transporting heavy equipment in huge manufacturing workshops, handling batch after batch of goods in logistics centers, or executing precision control in the semiconductor or pharmaceutical industry; electric tugs are able to equip appropriate tools or accessories to handle various scenarios. The ability of carrying any type of cargo through changing different towing tools with strong compatibility and high adaptability.

In the case of many electric tugs which are working in different operating environments, there is usually more than one option of function, such as anti-slip wheels, additional suspension devices to fit uneven ground, or added dust covers to protect goods from external pollution. The multifunctional design enables an electric tug to work stably in various working environments without the need for multiple devices to work together. As a strong tool, electric tugs are able to enhance productivity and reduce operating costs for industrial automation, warehousing logistics, and the precision manufacturing industry. Its multi-purpose application value will also provide a new approach for enterprise optimization with regard to resource allocation enhancement and enhancement of site flexibility.