What Makes Electric Tow Tractors the Best Choice for Airport Use

Electric tow tractors are ideal for airports because they have a towing capacity of 70 tons, produce zero emissions, and have 25% lower maintenance costs. With additional features such as regenerative braking and anti-collision sensors, they offer a package of safety, efficiency, and environmental compliance that cuts carbon footprints by 50 metric tons annually per unit.

Efficient Baggage Handling

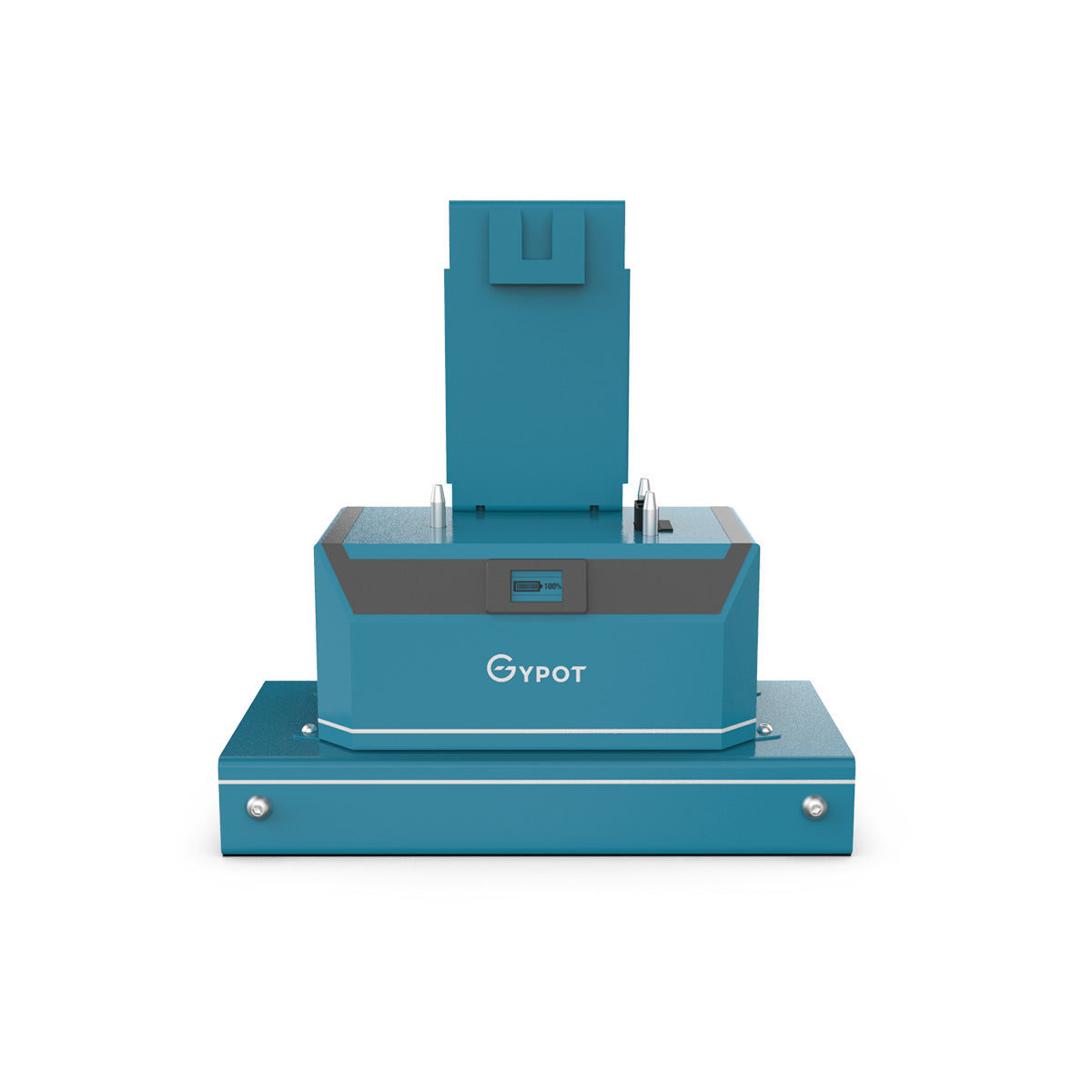

ETTs revolutionize the concept of efficiency in baggage handling with their unparalleled precision and performance. These vehicles have been designed to operate with optimized torque delivery, consistent and irrespective of the weight of the load-a prime feature in an environment where downtime or delays can make or disrupt the schedule of an airline. A typical example is the GYPOT E-Trac 4000, with its high-level torque converter system that offers smooth hauling at up to 40 tons and meets even the busiest of airport operations.

Apart from the load capacity, precision control systems in ETTs also provide smoother maneuvering within crowding terminal environments where space is usually limited. During comparative testing, ETTs reached 15-20% faster transfer times compared with their diesel versions, because of their zero-delay acceleration profiles that reduce the risks of misplacing luggage during high-traffic hours. According to reports, major airports like Dubai International have noticed an operational improvement of over 18% in baggage transit cycles by replacing outdated models with electric ones.

Additionally, electric tow tractors have regenerative braking systems that extend hours of operation at full performance. These systems convert kinetic energy back into battery power, which in turn provides an extended range for the ground handling teams to handle multiple flights before recharging is required. This feature has been highly useful at airports such as Frankfurt, which moves in excess of 500,000 baggage units on a daily basis, and where reliability of equipment is key.

Eco-Friendly Operations

Environmental sustainability has now become a major talking point for the aviation industry, within which electric tow tractors are very vital for reaching carbon-neutral objectives. Unlike other conventional internal combustion engine vehicles, ETTs emit zero localized emissions and hence make it quite easier for airports to align themselves with international initiatives such as the International Civil Aviation Organization Carbon Reduction Program. Furthermore, by replacing a single diesel tow tractor with its electric equivalent, the airports can reduce their greenhouse gas emissions by about 50 metric tons of CO₂ annually, equal to taking 10 passenger vehicles off the road.

Another major plus of ETTs is their high energy efficiency. Powered by lithium-ion or nickel-metal hydride (NiMH) batteries, these vehicles convert over 85% of their energy into propulsion, while the 30% limit for diesel engines is a far cry. Airports such as Heathrow and Changi have reported a 25% reduction in energy costs after making the transition to electric ground support equipment, demonstrating different proportions of both ecological and economic benefits.

Besides, ETTs make airports comply with the growing stringency of noise and pollution levels accompanying proximity to cities. In states like California, where airports like San Francisco International must adhere to very high environmental standards, electric tow tractors provide a means of meeting such requirements with no compromise on productivity. For example, noise pollution in areas around taxiways has decreased by 35%, among other positive effects, after electric equipment was put into service.

Low Maintenance Costs

One of the major benefits of electric tow tractors is the lower maintenance requirements. Since they have fewer moving parts, the chances of mechanical failure are considerably reduced. Diesel models commonly require oil changes at every 300 hours and filter changes at every 500 hours, which not only translates to considerable down times but also labor costs associated with such activities. By contrast, ETTs like the GYPOT Lithium Series need only periodic software diagnostics and battery health checks.

This can translate into as much as $10,000 per vehicle annually in savings for airport maintenance. Such savings come from extension of service intervals, fewer wear-and-tear components, and absence of consumables like engine oil and coolant. Tests at Munich Airport have shown that their fleet of electric tow tractors ran 25,000 hours before replacement of major components was needed-a duration twice that of similar diesel models.

Besides, most electric versions come fitted with predictive maintenance technology that utilizes IoT sensors to monitor critical systems in real time. Certainly, this proactive approach reduces unplanned downtimes as technicians get warnings of potential issues before they become operational problems. In short, battery performance anomalies-which comprise 12% of fleet issues-can be diagnosed remotely to make certain continuous service is uninterrupted by delays on site.

Enhanced Safety Features

Safety is one aspect of airport operations, and electric tow tractors represent the latest systems designed to minimize risks. Advanced safety features include anti-collision sensors, automatic speed limiters, and autonomous emergency braking (AEB), reducing accidents in high-traffic areas. These enable the ETT to detect obstacles within a 1-meter radius and automatically bring the vehicle to a stop to avoid collisions.

Another important role is played by ergonomics in ensuring operator safety. ETTs have considerably less vibration and noise compared to diesel models, reducing operator fatigue. For instance, the GYPOT ComfortDrive System features a shock-absorbing suspension seat and noise insulation panels for 40% improved operator comfort. Additionally, in-cab real-time telematics systems offer real-time data to operators on vehicle diagnostics and operational guidance, thus enabling better situational awareness.

Major airports, such as Hong Kong International, report a 25% reduction in workplace injuries since the transition to electric tow tractors with improved safety protocols. This reduction includes fewer cases of repetitive strain injuries because operators are no longer exposed to the constant vibrations and high decibel levels associated with diesel engines.

Versatile Applications

They could also function as baggage handlers, but their roles can easily expand to almost any other function needed for ground support; tractors are very useful in airport operations. Specific models, such as the GYPOT E-Trac Pro, use a system called modular coupling systems, which enable switching towing tasks between passenger stairs, cargo dollies, and even aircraft of small capacity.

In cold-weather airports, such as Oslo Airport, electric tow tractors with battery thermal management systems efficiently operate below zero. These systems maintain ideal battery performance by regulating the internal temperature, providing consistent output without regard to external conditions. Likewise, for hot climates such as Dubai, ETTs have been fitted out with active cooling technology where their reliability has been duly tested, providing peak performance above 45°C.

The versatility of the ETTs further extends to autonomous operations: some of their high-end models come fitted with automated guided vehicle, or AGV, technology that enables them to perform routine tasks independently, such as towing empty baggage carts back to the terminals. This feature not only increases productivity but also saves labor costs, making the ETTs future-proof.

Powerful Towing Capacity

Modern electric tow tractors have their design and construction focused on competing with, and sometimes even surpassing, their conventional diesel counterparts in terms of towing capacity. An example could be the GYPOT E-Trac HeavyDuty 7000, offering towing capacities up to 70 tons-thus highly relevant for airports dealing with large cargo volumes and wide-body aircraft.

In high-demand environments such as Los Angeles International Airport, which sees more than 1,000 tons of cargo moving each day, electric tow tractors have been able to sustain peak operations without sacrificing efficiency. Their high-torque electric motors guarantee immediate power delivery for smooth startups and accurate control when towing sensitive or high-value cargo.

In the higher-end versions of the ETT, the dual-drive systems share power equally among all the wheels for stability and sure-footedness on both uneven surfaces and inclines. In fact, in those airports with large tarmac layouts, towing distances could reach up to more than 2 kilometers in a single trip.

Benefits of Quiet Performance

Noise pollution is also increasingly a concern for airports, particularly those lying near residential areas. Most electric tow tractors function at an average noise level of 50-55 decibels, quite the contrast to roaring sounds of their diesel counterparts at 80-85 decibels. The major reduction makes the area more comfortable for ground personnel to work in and will more than likely be in conformance with much harsher local noise limits.

As an instance, Amsterdam Schiphol Airport has invested millions into electric tow tractors to meet noise compliance standards and reduced complaints by the surrounding communities by 40%. These low noise levels enable the ETTs to work even at night without causing disturbance to nearby residents, hence increasing operational flexibility.

Apart from community benefits, the quieter performance of ETTs also contributes to improved communication on the tarmac: the ground staff can raise instructions more effectively, thereby enhancing overall safety and coordination. This feature has been especially useful in airports like Tokyo Narita, where simultaneous operations often require precision teamwork among several crews.