How Can Electric Tuggers Improve Safety in Industrial Workplaces

Electric tuggers enhance safety by reducing manual strain, workplace injuries by up to 40%, and stabilizing loads of up to 5,000 kg-all with features that include automatic braking, zero-turn steering, and anti-tip technology for secure, precise movement in tight spaces and high-risk environments.

Reduce the Risk of Manual Labor

Electric tuggers play a critical role in ensuring that the physical demands put on workers within an industrial setting are greatly minimized. They are important in ensuring a greatly reduced risk of musculoskeletal disorders. According to the Bureau of Labor Statistics, 30% of workplace injuries in manufacturing arise from overexertion caused by manual lifting, pushing, and pulling activities. Electric tuggers are designed to alleviate these risks by automating the process of moving heavy loads, reducing the required force exerted by operators to less than 10% of the load weight.

For example, in automotive manufacturing plants, electric tow tractors are being utilized to deliver engine assemblies weighing upwards of 4,000 kilograms over production lines. These units replace manual labor that previously relied on teams of 5-6 workers to mobilize the load, greatly minimizing the possibility of strain-related injuries. Not to mention, electric tuggers will further enhance the efficiency in the workforce because the physical workload is well distributed to allow operators to perform higher-value tasks without fatigue.

In airport ground handling, electric baggage tuggers streamline the transportation of luggage across terminal facilities. According to research by IATA, electric tuggers reduced baggage-related worker injuries by 55% over three years. Additionally, these machines include ergonomic enhancements that minimize repetitive motion injuries to further enhance operator safety by providing adjustable handles and hand-operated throttle controls.

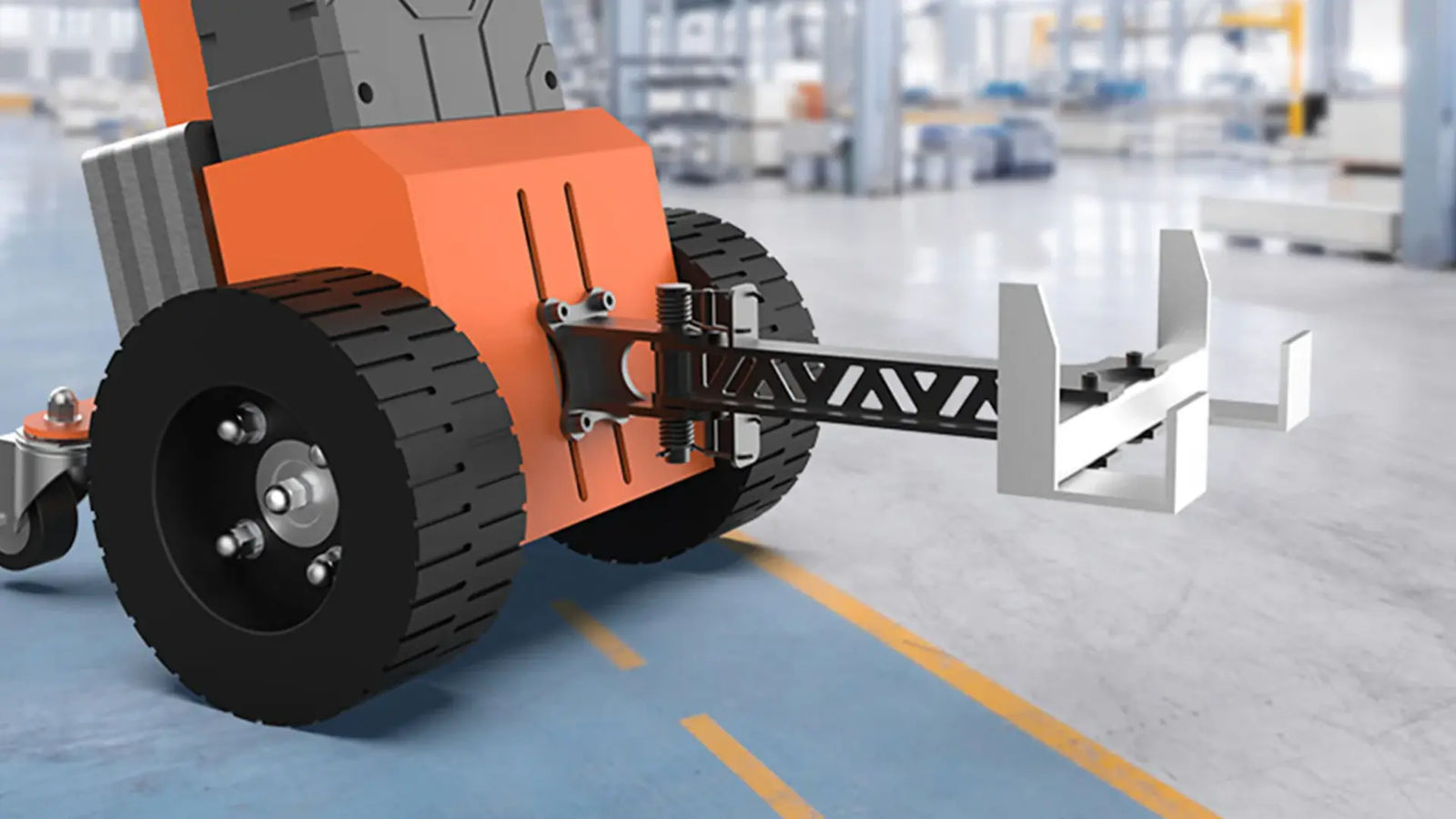

Improving Load Stability

Among the critical challenges in industrial load handling, stability is crucial, especially when it involves the transportation of heavy or unevenly distributed materials. Advanced stability control systems come installed in electric tuggers, such as anti-tip technology, automatic braking systems, and low-center-of-gravity designs, which mitigate the risk of load imbalance.

For example, electric tuggers offer smooth, consistent acceleration in warehousing and distribution centers where materials are usually stacked on multi-tiered carts. It eliminates sudden jerks or vibrations that may cause displacement of the load. In one case study in a pharmaceutical warehouse, the product breakage rate decreased by 30% to ensure fragile medical supplies were being delivered much safer.

The flower industry utilizes electric tuggers to move around wheeled carts full of plants and flowers across uneven warehouse surfaces. Load-sensing technology, part of the units, instantly detects changes in the distribution of weight on the carts and self-corrects with speed and directional changes. Indeed, studies have demonstrated that cart tipping incidents have reduced by 40% through the use of electric tuggers within flower warehouses, which saved products and operational downtime.

Apart from this, electric tuggers are also quite frequently endowed with dynamic traction control systems for managing even extremely slippery surfaces. Just consider supermarket logistics, for instance, depending on those systems that guarantee to move heavy snack carts along polished aisels without slipping or loss of stability for the products' and personnel's sake.

Improving Operator Control

Electric tuggers are all about prioritizing operator control through the integration of intuitive user interfaces, ergonomic designs, and precision steering systems. Unlike manual tuggers or forklifts, electric models sport dual-speed controls that allow operators to dynamically adjust speeds depending on load weight, floor surface, and operational requirements.

For instance, in automotive production lines, where precision becomes critical, operators use electric tuggers with electronic steering assist systems that afford ultra-precise control. These make cornering smooth and assure negotiation of narrow pathways without risking collision. Besides, functions such as programmable acceleration curves ensure there is no sudden jerk when building up speed, which will compromise the stability of a load.

In addition, electric tuggers are equipped with deadman controls: a fail-safe that stops movement instantaneously if the operator releases the handle. This is quite prevalent in industries like aviation ground handling, where instant stops are necessary to prevent damage to very valuable assets, such as aircraft fuselage components.

Electric tuggers also use intelligent navigation technology, including GPS tracking, automatic obstacle detection, and proximity sensors. Minimizing human error by up to 30% in the context of warehouse logistics, the technology enables the safe transportation of goods through high-traffic areas. Operators receive real-time notifications alerting them to route obstructions, load imbalances, or speed limit breaches that further ensure workplace safety.

Preventing Workplace Accidents

The automation provided by electric tuggers greatly reduces the chances of workplace accidents, especially within high-risk industries such as manufacturing, logistics, and airports. According to OSHA, the deployment of powered equipment like electric tuggers has achieved a 40% reduction in workplace injuries related to heavy load handling over the past decade.

Electric tuggers are also being used to tow baggage carts across busy tarmacs in ground operations in aviation. Many units of today feature proximity alarms and collision-avoidance systems that can detect obstacles in a 2-meter radius. These systems immediately bring into effect either a slow-down or stop function to prevent an accident caused by operator oversight. The implementation of such electric tuggers was responsible for the reduction in on-ground incidents by up to 25% in major airports, like those of Dubai and Frankfurt.

In addition, electric tuggers used in warehousing operations are now fitted with LED safety lighting combined with warning alarms to alert workers in close proximity to the movement of the machinery. These features are particularly useful in averting accidents in poorly lit storage facilities, with statistics showing a 15% decline in collisions due to pedestrian-machine interactions.

Safe Navigation in Tight Spaces

Electric tuggers are specifically designed for compact maneuverability to enable operators to operate in tight spaces safely. Most of the models feature zero-turn radius steering, which enables them to make sharp turns within confined pathways, such as crowded warehouses, supermarkets, and manufacturing plants.

In electronics manufacturing plants, for instance, where components are put together in confined production lines, electric tuggers equipped with integrated auto-steer technology enable seamless navigation through pathways as narrow as 1.5 meters. This machine can transport heavy components without hitting surrounding equipment and guarantees the safety of both products and workplaces.

In supermarkets this product is used for pulling in snack carts or promotional displays. Their low profile design means they don't impede customer traffic and also feature non-marking tires so your floors aren't damaged. Some of the retail chains said increased efficiency by as much as 20 percent when trading out manual tugs with electric ones for operation through tight storage and narrow-aisle spaces.

Lowering Fatigue-Related Errors

Fatigue is one of the major factors contributing to errors and accidents in industrial environments. Electric tuggers considerably reduce operator fatigue by automating the movement of heavy loads, thereby enabling workers to complete their tasks with minimal physical strain.

For example, in high-volume flower distribution warehouses, employees often travel with carts over a long distance. By incorporating electric tuggers, loads are pulled with more than 75% less effort required, which allows an operator to move up to 60 carts per hour without becoming fatigued. The effect of this is that it reduces operator errors while creating a significant improvement in productivity.

In automotive manufacturing, operators using electric tuggers report a 20% improvement in task completion rates as they can focus on precision assembly tasks rather than expelling energy on manual transportation. This directly contributes to fewer human errors, improved production quality, and safer working environments.

Ensuring Smooth Heavy Load Movement

They make certain that the electric tuggers work with smooth and controlled movements, especially in a high-volume industrial operation. In fact, many modern units are equipped with hydraulic weight distribution systems and smart torque control, which further optimize performance with any given load.

In car manufacturing plants, for example, electric tuggers can handle chassis parts with weights in excess of 5,000 kg without compromising load stability or inducing vibrations that may damage components. In one manufacturing plant, a 15% reduction in product damage was recorded after the deployment of electric tuggers with smart load management systems.

In large-scale warehousing, electric tuggers with constant-speed governors ensure consistent movement, even when navigating ramps or inclines. For instance, in logistics facilities that handle fragile goods, these features have helped reduce breakage incidents by 25%, ensuring smoother delivery and higher operational efficiency.

Moreover, electric tuggers fitted with anti-rollback systems ensure even greater safety when moving loads along inclined surfaces. This feature is especially useful in multi-level production facilities where the risk of manual handling is increased by gravity.