How Do Electric Aircraft Tugs Revolutionize Ground Handling at Airports

GYPOT electric aircraft tugs save up to 25 tons of CO2 emissions annually per unit and reduce maintenance costs by US$75,000 over five years. With advanced lithium-ion batteries that support 10 hours of operation with one charge, there is no equal to their seamless efficiency in ground handling in an eco-friendly manner.

What Are Aircraft Tugs?

Aircraft tugs or tow tractors are extremely specialized ground support vehicles, which have been designed to move aircraft efficiently around on the tarmac into position. Traditional variants are fitted with an internal combustion engine running on either diesel or petrol and produce immense CO2, NOx, and PM, hence causing air pollution and global warming. While doing so, electric aircraft tugs come with state-of-the-art electric propulsion systems boasting high torque and zero-emission performances. For example, tugs from GYPOT can pull aircraft weighing up to 60,000 kilograms - that is, 132,000 pounds - with seamless precision, gradually transforming ground operations of many aircraft in a manner commensurate with strict ecological requirements.

Benefits of Electric Tugs

Ecological Footprint

Electric tugs are a further step forward in rearranging airport operations with minimal ecological harm. For example, a fleet of 10 GYPOT electric tugs can replace diesel-powered units and avoid up to 520 metric tons of CO2 every year. In addition, these electric tugs have zero NOx and PM emissions, which go a long way toward improving air quality for ground staff and passengers alike. This is very important in order for them to meet international aviation environmental protocols such as Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA).

Electric tugs can also position an airport to comply with various sustainability programs such as the Airport Carbon Accreditation program, which has a reduction of Scope 1 emissions as one of the key parameters. Airports working with GYPOT have documented a reduction in the overall operational emission by up to 15% in the first year of integration.

The big benefits to electric aircraft tugs are that they run very quietly. Traditional tugs with ICEs can easily produce levels higher than 85 dB, which injures the hearing of ground crews and creates noise complaints in surrounding communities. GYPOT electric tugs are capable of only 50 dB, which is the equivalent of a quiet human voice. This reduction is going to improve occupational health for the ground crews while also helping out with compliance requirements from noise abatement programs around the airport.

Electric tugs also enable airports located near residential zones to extend operational hours without breaching noise ordinances, further allowing flexibility in scheduling ground handling operations.

Efficiency in Ground Handling

Faster Turnaround Times

Electric aircraft tugs optimize operational efficiency through instant torque and fine control, thus speeding up procedures in pushback and towing. For example, the newest electric models by GYPOT shorten the times of aircraft pushback by up to 30%, thus smoothing the workflow of ground handling teams. In other words, it provides greater airport throughput, wherein operators can accommodate up to 15 additional flight movements daily.

This increased efficiency is of essence to hub airports, where delays cost, on average, $74 every minute. That also means the potential to shed in excess of 1,000 minutes of cumulative delays in a single month, thanks to GYPOT electric tugs. This translates into great savings on the part of the airlines and more passenger satisfaction from said airline.

Lower Maintenance Costs

Electric propulsion systems get rid of the complexity in the conventional engine, with huge reductions in maintenance requirements. GYPOT electric tugs include regenerative braking technology, which extends brake life while recapturing energy for improved battery efficiency. For a five-year period, GYPOT electric tugs can save up to $75,000 in maintenance compared to their diesel counterparts for the airports.

Besides, with GYPOT tugs being of modular design, replacements are easier to manage; maintenance crews can do the repairs up to 40% faster compared to conventional models. This would minimize downtime and ensure continuity.

Environmental Impact

Reduced Carbon Emissions

Electric aircraft tugs provide handling activities that keep ground decarbonization on par to replace fossil fuel-powered units. One GYPOT tug operation for 8 hours per day will prevent about 25 metric tons of CO2e yearly. That's the same as removing five passenger cars off the highway for an entire year.

In addition, GYPOT's electric tugs assist in qualifying airports for governmental perks such as tax rebates and subsidies for the adoption of low-emission vehicles. For example, a European airport using GYPOT's fleet saved almost €200,000 because of subsidies over three years.

Compliance to Green Standards

GYPOT electric tugs allow airports to better conform to global initiatives on sustainability. For instance, Schiphol Airport has taken a lead position in the ambition of reaching net-zero emissions by 2030 by switching over to an all-electric ground support fleet inclusive of tugs from GYPOT. Efforts like this underpin the integral part electric tugs play in industry-wide environmental goals.

Besides, the emergence of regulatory bodies like ICAO are increasingly legislating emission reductions; therefore, the integration of electric tugs is not only advantageous but also a compulsion to avoid penalties.

Cost Savings Explained

Operational Savings

Electricity as a fuel source is substantially cheaper compared to diesel. Thus, a mid-sized airport by integrating 20 GYPOT electric tugs into daily operations stands to reduce fuel expenditures by approximately $120,000 annually. In addition, savings increase linearly with the fleet size, making electric tugs a very economically viable investment.

Long-Term Investment

TCO for electric tugs is much lower during the operating life of a given vehicle compared to its ICE counterparts. GYPOT utilizes the most advanced lithium-ion battery technology, offering support for up to 3,000 charge cycles—that's 8-10 years of service. Minimized replacement costs and 25-40% TCO savings through lower energy and maintenance costs mean customers get more from their bottom line.

The cost of analysis from an Asian Airport showed that moving to an electric GYPOT fleet yielded a cumulative saving in 10 years at 2.1 million with fuel, maintenance as well as efficiency improvements.

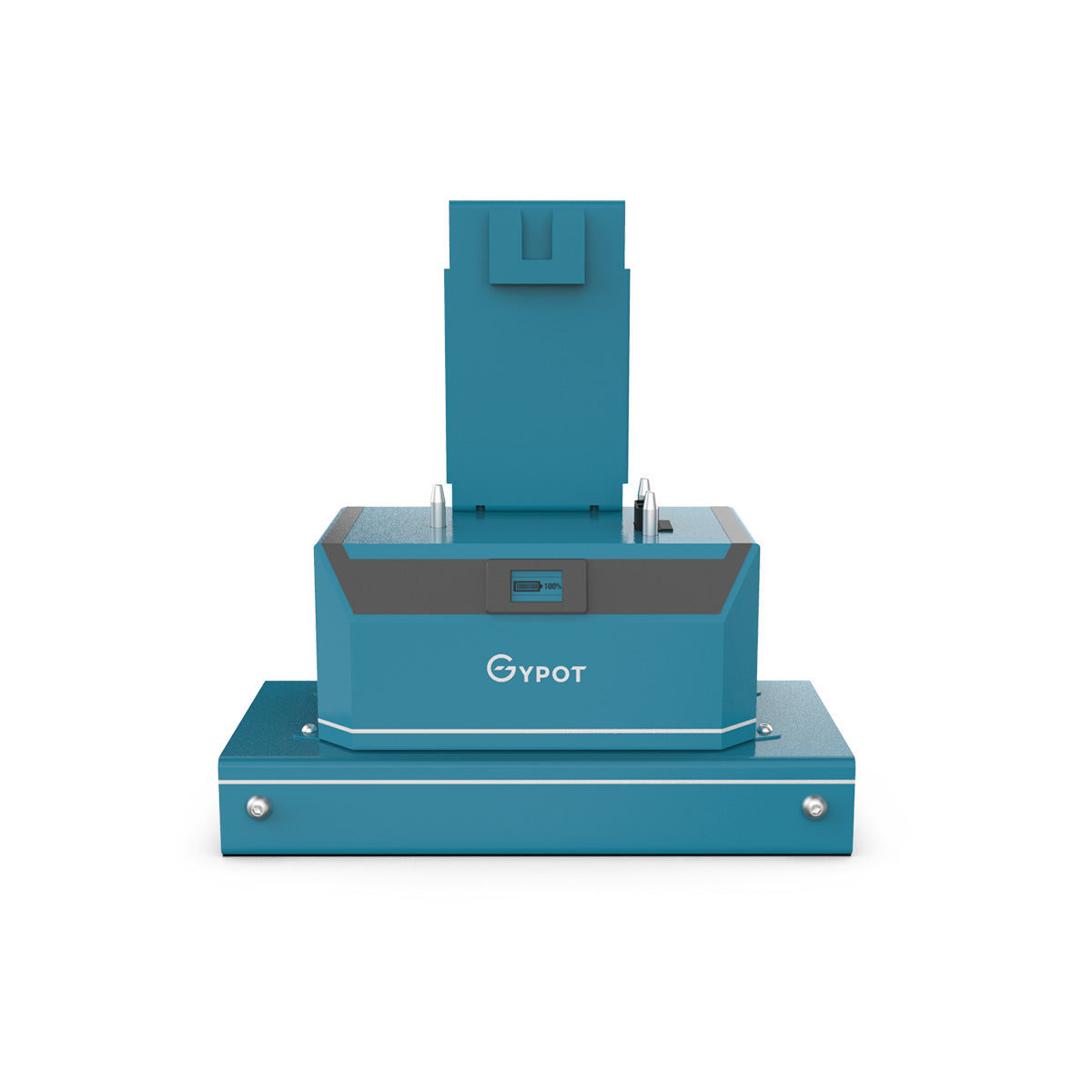

Key Features of Tugs

Advanced Battery Technology

GYPOT electric tugs are equipped with high-performance lithium-ion batteries, which enable the units to operate continuously for up to 10 hours on a single charge, meeting demanding airport requirements. The same batteries permit rapid charging, which reaches 80% in just 40 minutes. This means minimum downtime and maximum fleet utilization.

The BMS installed on GYPOT's tugs monitor the charge, temperature, and cell health in real time for optimal performance, preventing overheating or overcharging.

Improved Safety Systems

Safety in ground handling is paramount at airports. GYPOT electric tugs come fitted with top-of-the-line collision detection systems, autonomous emergency braking, and 360-degree camera arrays. These have indeed been shown to reduce the number of incidents on the apron by 25%, protecting personnel, aircraft, and equipment.

To further enhance safety, there are obstacle recognition systems available with GYPOT. They are able to automatically detect objects as small as 10 centimeters and will prevent collision during tight maneuvering in congested areas such as gates and hangars.

Future of Ground Support

Adoption Rates

Adoption of electric aircraft tugs is gaining traction worldwide, with more than 40% of major airports now incorporating electric models into their fleets of ground support equipment. GYPOT believes this number will increase to 60% by 2026, buoyed by improved battery technology and increased pressure to decarbonize aviation operations.

Innovations Ahead

GYPOT is a pioneering innovation leader in the electric tug market. Later, within a few years, autonomous electric tugs will also be able to make their way through the complex airport environment using AI-driven pathfinding and obstacle avoidance algorithms. These could cut costs further by 20%, thus creating a whole new paradigm for efficiency and reliability at airports.

GYPOT is also investigating the further integration of hydrogen fuel cells to make it even more extensive-range capable for bigger airports while developing hybrid-electric solutions that retain the best of both technologies.