The Benefits of Powered Tugs in Material Handling

Powered tugs, driven by electricity and equipped with intelligent designs, enhance the efficiency and safety of material handling, reducing risks and costs associated with manual labor. They are widely used in manufacturing, logistics, and other industries, playing a crucial role in optimizing handling processes and increasing productivity for modern enterprises.

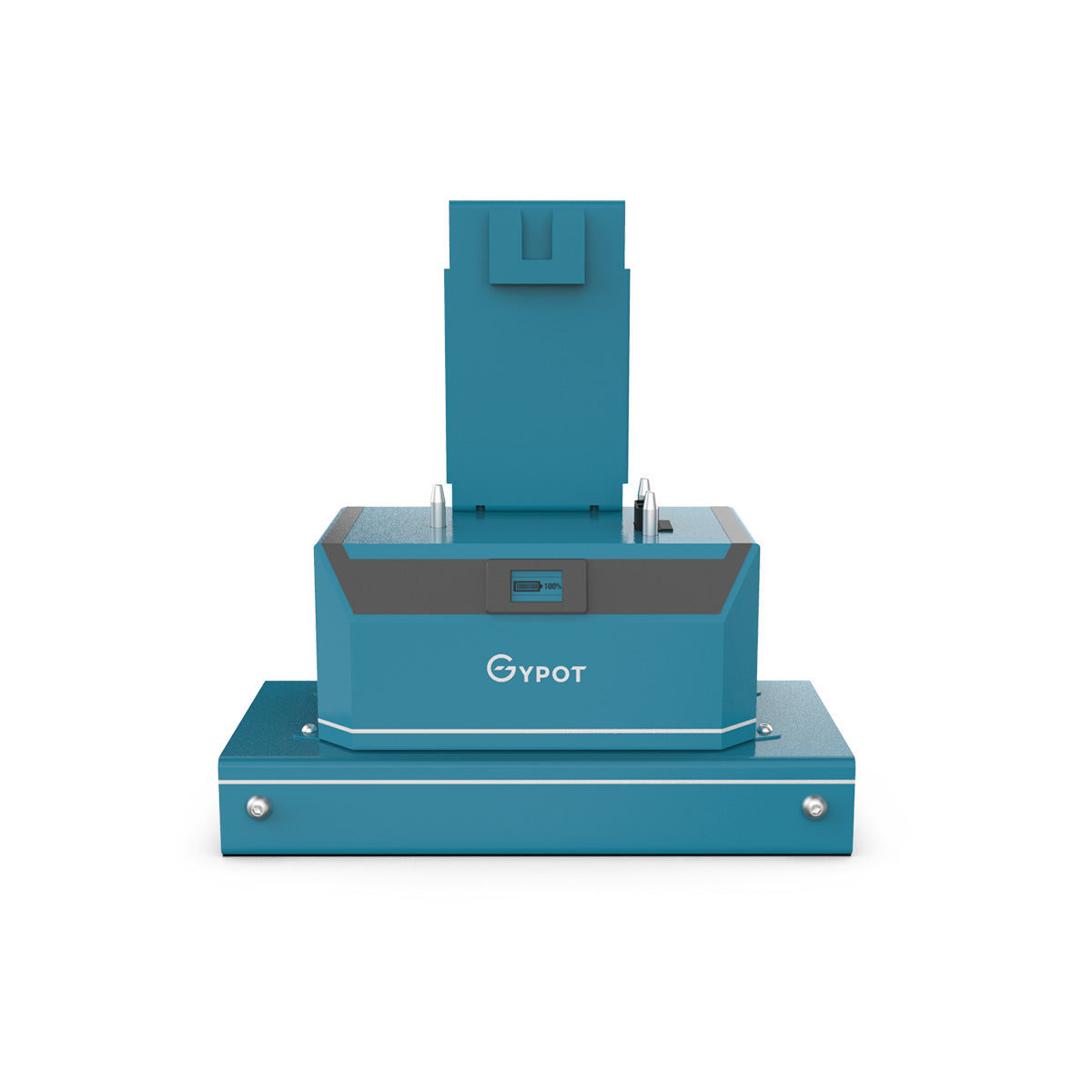

What Are Powered Tugs

Giant battery-powered tugs are contemporary industrial tools for handling that really prove the sincerity of the motto that production should be easy for both laborers and business. Their patterns are simple but very efficient: electric power and mechanical transmission induce the immense pulling force that draws from one and moves it smoothly yet controllably. For example, these kinds of devices may carry weights of hundreds of kilograms into tons without the least human effort.

Build of small build usually occupies a powered tug into very hearty features. A common powered tug would typically come along with very high-performance batteries, allowing it to run for many hours or even a whole day, with special arrangement for high-frequency and high-intensity work environments. The handle and control system of this powered tug shall be well-designed to ensure it remains intuitive such that even those with no knowledge can easily learn to operate it.

The tires and chassis of power tugs are specially reinforced structure features to make them possible to travel through a variety of ground conditions. The powered tug can still show exceptional performance whether on smooth workshop floors or slightly contused outdoor terrain. That makes them most well equipped to be within any industry, doing a vast majority of material handling applications.

How They Improve Safety

Hoping to bring the traditional "brute force over brains" to a close, powered tugs have very much revolutionized safety into material handling. Now, it has become a very safe and very dependable work environment.

Consider the average handling case: a worker has to move a few hundred kilograms of goods with a hand cart a few meters away. Even the most consummate skilled hands sometimes bring on accidents via either unbalanced weights or overexertion. Powered tugs could adjust the load and pulling speed automatically, and with that, worker error chances would go down drastically.

Also, powered tugs have many inbuilt safety features. When the equipment senses that there's too much load, or if it is on a steep incline, it automatically generates an alert about the situation while reducing speed to avert accidents. Some of the high-end models even have infrared sensors and collision-avoidance systems by which the devices are able to check out the surrounding environment and preclude collision in real time.

They could save costs for managers by lessening the chances of injury from heavy lifting in the workplace; thus, they avoid some unnecessary expenses for medical treatment or lost time—precisely the kind of priceless safety strategy in a highly competitive market.

Boosting Efficiency in Workflows

The contribution of powered tugs to enhance the working efficiency is alike with that role, which lubricant does in machine operation—smoothens and improves the process, whether in industrial manufacturing or in warehouse logistics. The power tugs improve the work process much better, even with their small physical presence.

In production lines, powered tugs can be the "link" between the workers and the machines. The production line constantly requires replenishment of components, and powered tugs can flexibly shuttle between workshops, delivering materials quickly and preventing production stoppages; therefore, the provision of this continuous, efficient supply model saves precious time for businesses.

In logistics centers, these powered tugs can boast rather impressive handling capabilities. Where an employee might have to trek back and forth repeatedly with small loads, a powered tug can do the work with each single trip, transporting multiple pallets or even tons of cargo. It eliminates trips and lets employees concentrate on really important things like sorting goods and inspection for quality.

The efficiency of powered tugs is not independent. Many companies have integrated them along with automated software and RFID systems to complete the digitization of the entire process of material handling in the entirety of an organization. This interface between technology and manpower does not only reduce the time used in human intervention but also takes the levels of material handling efficiency to a new high.

Cost Savings Explained

Powered tugs are an investment that supplements implementation, delivering excellent savings in certain areas. The labor saving brought about by powered tugs is probably an immediate one-person operation capable of doing the job of several people and thus eliminates the need to hire temporary workers during peak periods.

Traditional manual handling burden long-enough lifting of heavy loads, which can lead to occupational illnesses or, in an instant, accidents that affect employees' health and have costly compensations. Powered tugs replace the workload intended for the human to mechanical energy, minimizing this risk and saving hidden costs for businesses.

As a result, maintenance and energy costs decrease. Thanks to their electric drive, these powered tugs consume much less energy, unlike diesel- or gas-powered vehicles. Also, many of these powered tug models are designed simply, and their core components have long maintenance cycles. Immediately after purchase, these high-performance devices are then expected to perform over long periods with minimum worries about frequent maintenance expenses.

Applications Across Industries

Every industry has different requirements, and powered tugs provide versatility with their application and has so far embedded itself in these industries as the universal key to material handling.

In the automotive manufacturing industry, companies employ them to transfer components across production lines. This high-precision movement signals a need for equipment that can move parts to determined positions quickly and steadily to avoid disturbance in the process of assembly. A very typical application for powered tugs is material handling in the food processing industry. These applications would demand the maximum possible hygienic conditions because of their zero-emission electric nature.

The segment where they are widely adopted is logistics. From warehousing to sorting to loading onto trucks, they are found everywhere along the logistical chain. In the medical sector, they have very specific functions, like transporting big medical equipment or medicines, keeping material flows smooth while reducing the manual workload on healthcare personnel.

In even giant retail shops or warehouse outlets, powered tugs are used to supply bulk loads of goods into smaller cells. They save times and make restocking shelves more efficient. Their adoption across wide industries gives testament to their flexibility and versatility.

Choosing the Right Tug

Selecting any tug suitable for your requirements shall be both technical and strategic. It will include assessing the ability of the equipment as well as the operation of the business. The very first assessment is going to be about the working environment. The small powered indoor tug may have to be more agile; the outdoor model would most likely require more weather resistance.

Other particular critical factors are load capacity and battery life. If this device is to be used long or under heavy work conditions, it will be more logical to choose that device with a more voluminous battery and fast charging. For lighter work, a cheaper option will usually do the trick.

The other auxiliary area much important is service availability and spare parts. A powered tug should not just accomplish the requirement in ways of use but also has good after-sales service, especially for critical components. Smooth supply chain replacement parts are crucial to ensure that the smooth running of equipment is maintained. Therefore, while buying, one should consider more than just price—the long-term benefits need to be kept in perspective.