tugger Blog

Remote control technology allows operators to guide electric tuggers from a safe distance, reducing physical strain and improving load visibility. This enhances efficiency by 40%, cuts labor costs by 20-30%, and reduces collision incidents by 70%, making it ideal for tight spaces and...

Continue reading

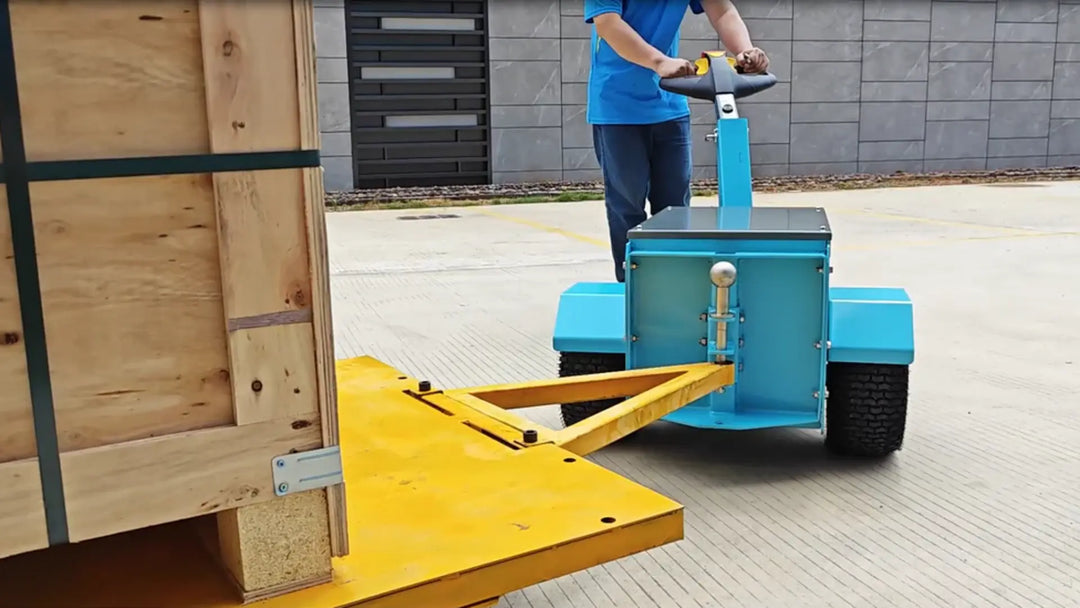

The NBT15 tugger is popular due to its 3,400-pound capacity, 8-hour battery life, and 15% slope handling. Its 500W motor boosts efficiency, while solid rubber tires last 25% longer. The automatic braking system reduces failure rates by 15%, ensuring safety and reliability in...

Continue reading

Brands with the best electric tugs warranty are KION and Crown Equipment. KION warranties 5 years for key components such as batteries and drive systems, which have a failure rate of less than 0.5%. Crown warranties as high as 7...

Continue reading

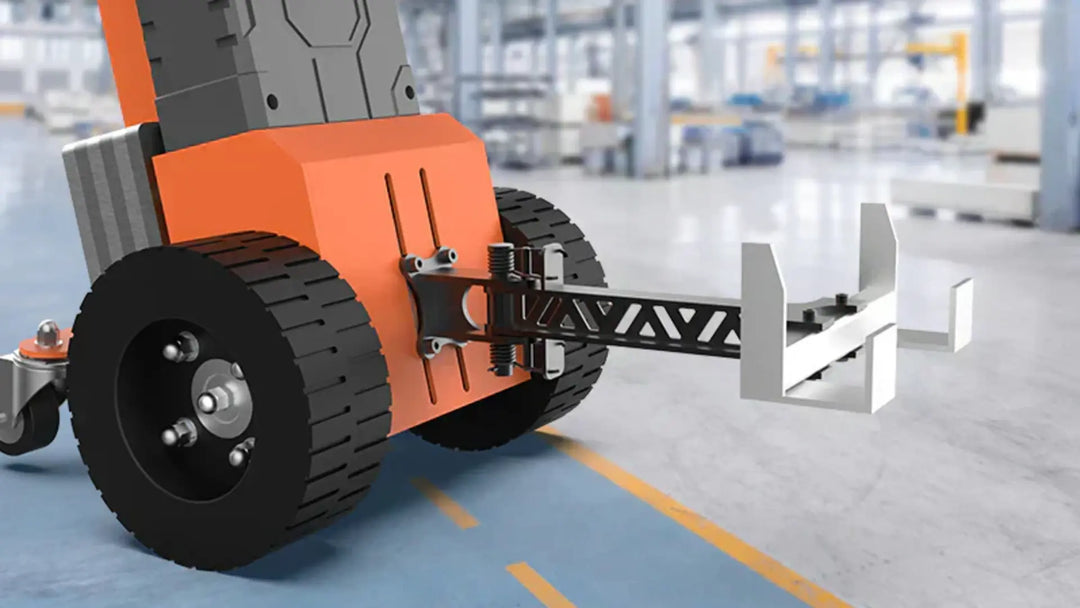

Using electric tugs in narrow aisles safely requires a speed limit of below 4 km/h in order to reduce the number of accidents attributed to speed by 25%, a precise steering control with electronic systems which means a reduced failure rate...

Continue reading

The yearly upkeep expenditure of industrial electric tugs generally amounts to an 8%-12% proportion of the initial purchase price. For example, the maintenance could amount to about $4,000-$6,000 in case the tug is purchased for $50,000. These expenses can be reduced...

Continue reading